E-poçt formatında xəta

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Xəbərlər

What Is the Role of Automotive Die Castings

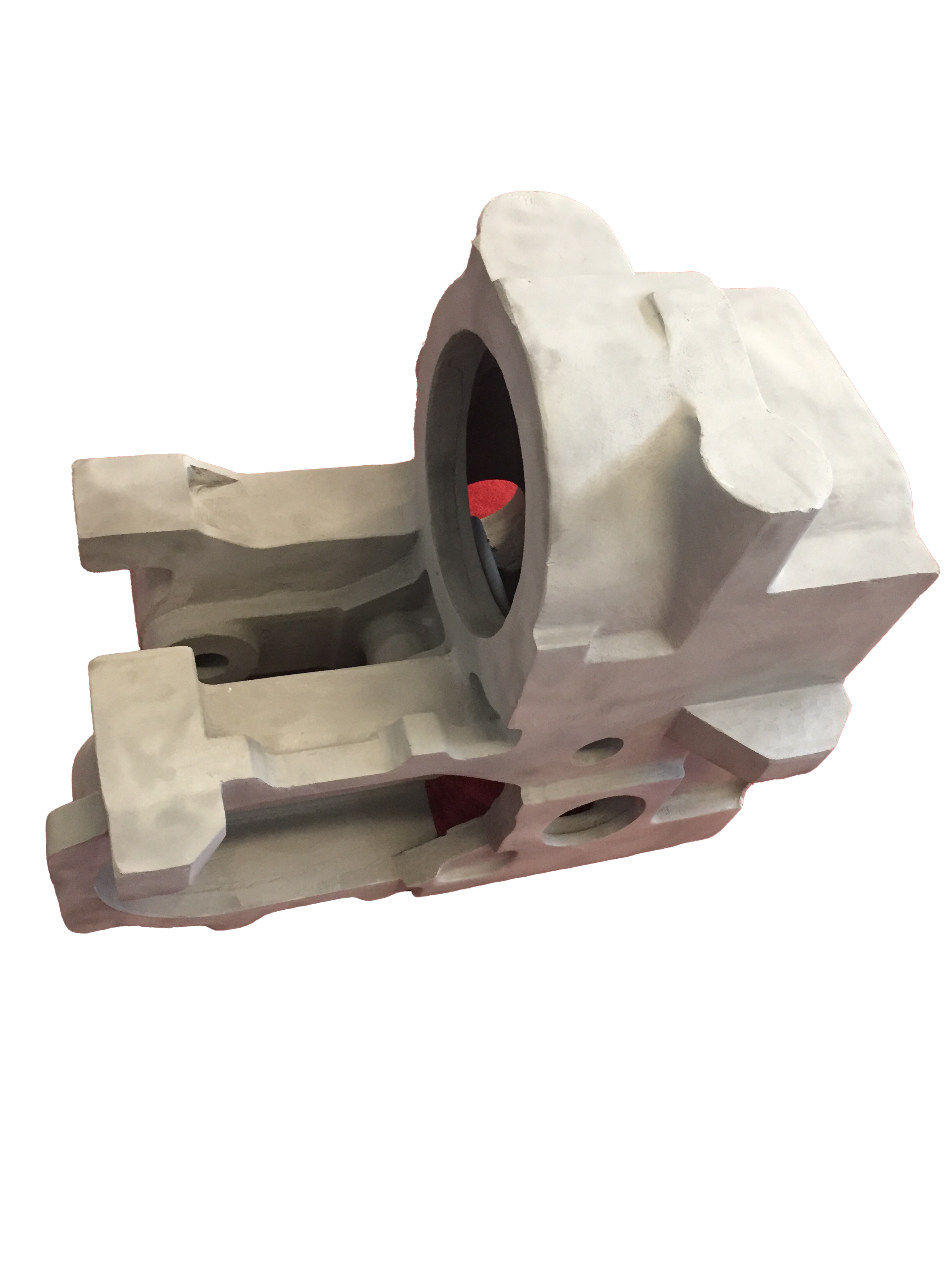

Die casting is a part obtained by using die-cast aluminum to open a mold, and then heating the cast aluminum to melt into a liquid and fill the cavity.

What are the materials of die castings?

Die casting is a conventional process for the production of auto parts. It is a process of organically combining the three major elements of a die casting machine, a die casting mold and an alloy for comprehensive use. The metal materials used in die casting are mainly aluminum alloys, magnesium alloys, zinc alloys and copper alloys. Based on the excellent characteristics of aluminum alloys, aluminum alloy die castings are widely used in the automotive industry.

In the automotive industry, the common processes of aluminum alloy casting include gravity casting, semi-solid casting, low pressure casting, differential pressure casting and high pressure casting. In recent years, high vacuum die casting technology has been widely used by enterprises in the industry.

What are common die castings?

Die-casting parts can be manufactured as die-casting auto parts, die-casting auto engine pipe fittings, die-casting air-conditioning parts, die-casting gasoline engine cylinder head, die-casting valve rocker arm, die-casting valve seat, die-casting power fittings, die-casting motor end cover, die-casting housing, die-casting pump Shell, die-casting building accessories, die-casting decorative accessories, die-casting guardrail accessories, die-casting wheels and other parts, with the continuous improvement of the development level of the domestic manufacturing equipment industry, the equipment level of the die-casting machine has also been significantly improved, and the types of parts that can be manufactured are also increasing. With the expansion, the precision of the die-cast parts and the complexity of the parts have also been greatly improved. I believe that in the near future, the die-casting parts will better serve our production and life!

Industrial chain

The upstream of automotive aluminum alloy die-casting is mainly aluminum alloy raw materials, die-casting equipment, stamping equipment and industrial robots. Representative enterprises include LK Technology, Yizumi, Baichu Electronics, etc.;

The midstream is mainly divided into two categories: parts suppliers and automobile assembly plants. Among them, parts suppliers have technological and scale advantages in die-casting products in subdivisions, such as Aikido, Wencan Co., Ltd., Xusheng Co., Ltd., etc. The factory is the supplier of the body, chassis, and powertrain, and has the advantages of customers, such as ZF;

The downstream is mainly OEMs. At present, new energy vehicle OEMs are the main downstream customers, including Xiaopeng, Weilai, Tesla, etc.

Why are die castings becoming popular?

There are three main processes of stamping, casting and forging in the die-casting part of auto parts. The trend of lightweight automobiles and the rapid growth of the new energy vehicle market has increased the demand for aluminum for automobiles, and key parts are developing in the direction of high-pressure die-casting, large-scale, and integration.

The advantages of the integrated die-casting process include: reducing the manufacturing cost of a single vehicle (the rear floor of the steel-aluminum hybrid vehicle Model Y can be made into an aluminum alloy integrated die-casting part, and the cost can be reduced by 40%. higher); reduce accumulated errors, improve production yield; simplify the manufacturing process and supply chain cycle, improve production efficiency.

Conclusion

If you are looking for an automotive die casting manufacturers,die cast aluminum heatsink,auto parts die casting manufacturer, we hope we will be your best choice.